Passion for innovation

Technologies for efficient painting and top quality

ensutec Products GmbH has been developing, producing and selling products to optimise painting work for more than ten years. The company is based in Langenenslingen, Swabia, and serves a wide range of industries with its systems. Numerous well-known companies and market-leading suppliers from all over Europe are among ensutec's customers. A growing network of trading partners also enables the company to competently serve international customer enquiries.

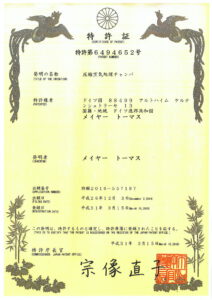

2001 Company owner and managing director Thomas Mayer (right) became self-employed: He founded the ensutec Engineering – Environmental and Surface Technologies, a consulting company for the optimization of painting systems. The graduate engineer was looking for ways to simplify the work of the painter and improve quality. The considerations culminated in the development of the airmatic atomization optimizationThis unique technology directs the compressed air through a specially developed high-voltage unit (EMP). The neutral electrical field ensures homogeneous and charge-neutral droplets. In addition, the compressed air is heated - or cooled if necessary. This guarantees consistent process conditions and ensures the best painting results.

2011 Thomas Mayer founded ensutec Products and began producing and selling airmatic systems. The first employees were hired for the production site in Riedlingen and the success story took its course: the company grew, the product range expanded and the production area was extended at regular intervals.

2015 ensutec Products GmbH equipped two Magna plants with the airmatic atomisation optimisation system and reduced paint consumption by more than 100 tonnes per year. As a result, the automotive supplier was not only able to save material and energy, but also noticeably reduce its emissions.

Driven by the entrepreneurial success, graduate engineer Thomas Mayer was appointed to the technical committee (FA) for production and automation technology at the German Research Institute for Surface Technology (DfO). ensutec Products GmbH has been 2016 Member of the DfO and actively represented in various committees.

From 2017 to 2019 became the technology in cooperation with the Esslingen University of Applied Sciences and the company BIX paintwork and in cooperation with the Fraunhofer Institute IPA scientifically investigated. This resulted in the latest EMP technology for paint atomization - with improved properties and results. After two and a half years, the result was available: It confirmed the effectiveness of the airmatic technology in an impressive way. (More information here).

2018 ensutec Products GmbH presented a new development: The airmatic revolution works by enriching the atomizing compressed air to almost 100 percent relative humidity, especially for the application of solvent-based paint systems. This is done using the basic additive femaBlue 2901. The system can also be enriched with other additives. The effect: significantly shorter drying times, particularly high-quality surfaces and cost savings in energy and resources.

2019 The new assembly and production hall with adjoining office wing in Langenenslingen was occupied.