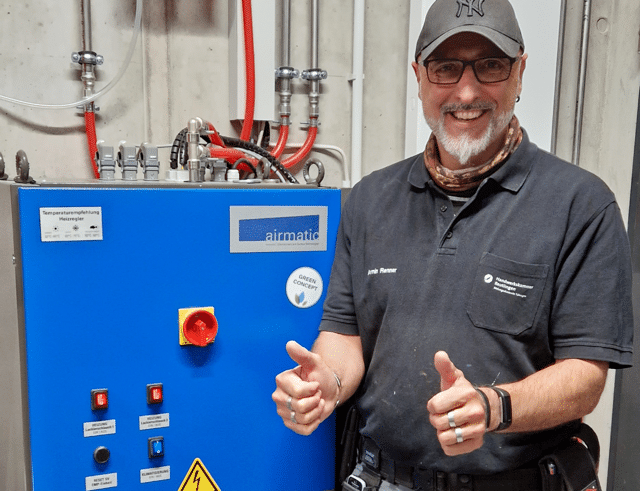

Training manager Armin Renner is proud of his ultra-modern paint shop at the Tübingen Education Academy. After commissioning two new paint shops, it was clear to the master painter and certified designer and interior designer: There is more to come! After intensive research and discussions within the industry, the Tübingen Education Academy decided to test the airmatic atomization optimization. The innovative technology is the patented system technology of the Upper Swabian company ensutec Products GmbH.

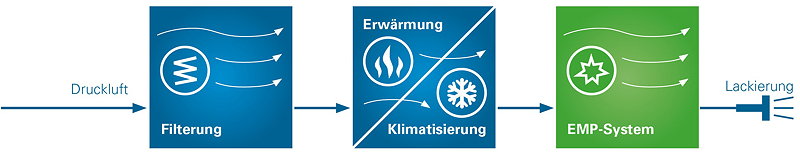

The airmatic technology can be used with any air-supported application technology and can be integrated into the existing system technology with little effort. The compressed air is passed through the specially developed high-voltage unit (EMP). The neutral electrical field ensures homogeneous and charge-neutral droplets. In addition, the compressed air is heated - or cooled if necessary. This guarantees consistent process conditions at all times.

The airmatic systems are available for both manual painting and robot systems. They are manufactured individually to meet the needs of each customer using a modular system. This means that small painting companies can be equipped just as optimally as large companies with several painting lines.

"At first we couldn't imagine that the effect would really be so great," reports Armin Renner. "But even with the first test panels with black high-gloss paint, we were amazed by the results: there were hardly any dust inclusions to be seen, and the rework could be reduced to almost 'zero'." The neutralized droplets result in fewer turbulences and runs. "This is not only more pleasant for the painters because less paint circulates in the air: it is also reflected in the reduced dirt in the paint booth," confirms Armin Renner.

Paint consumption has also been reduced since the airmatic system was installed. The savings potential of the airmatic technology has already been confirmed by an independent scientific study. The EMP unit from ensutec was examined as part of a project funded by the German Federal Foundation for the Environment (DBU). The measurements using laser diffraction spectroscopy show a broadening of the dynamic spray pattern and a significant increase in the application efficiency.

The trainees and future masters were also positively impressed by the handling of the airmatic system. "We hardly had to adjust to anything when painting, and the paint hose with integrated heating is easy and flexible to handle."

Armin Renner has been working for the Tübingen Education Academy for 25 years. "I am pleased that the technologies and paints have developed over the years to such an extent that perfect painting results can be achieved more sustainably and with less finishing effort," explains the training manager. Investments in modern technologies and work materials would therefore help companies to remain competitive in the long term and to use energy, resources and personnel as efficiently as possible. "Especially in times of a shortage of skilled workers, good workers also want to find optimal working conditions," confirms Armin Renner.

If you would like further information about the airmatic systems, please contact ensutec Products GmbH directly: by email info@ensutec.de or by phone +49 (0) 7371 96664-20).