airmatic atomization optimization

The innovation for automatic painting

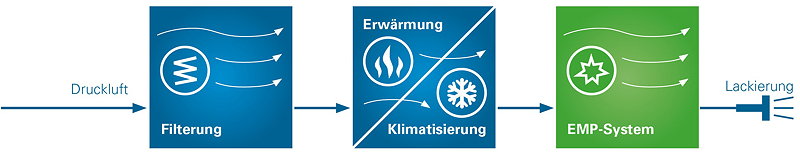

With the scientific investigation of EMP technology and the resulting further development of the components of our airmatic systems, we have achieved a quantum leap in automatic application.

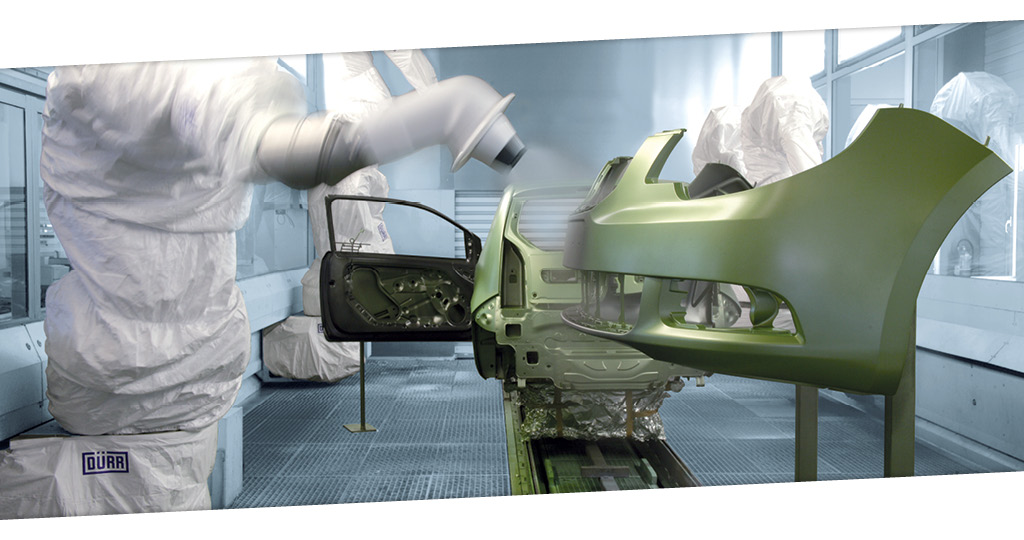

For automatic application with robots or multi-gun applications

The individual components provide all the prerequisites for high-quality and year-round process-reliable application of paints and coating materials.

The advantages of airmatic atomization optimization

- High paint quality

- Paint savings of 10 to 20%

- Less waste and rework

- optimization of the layer thickness distribution

- Better course

- Higher transfer efficiency

- Rapid amortization

- compressed air savings

- increasing material and energy efficiency

Easy and quick to install

- In addition to the existing application technology

- Can be retrofitted at any time without great effort

- Usually no significant changes to the painting system are necessary

The airmatic variants in the automatic paint finish

For optimal effect!

With the ATEX approval for our EMP technology it can also be used in painting areas of Zone 2(22).

EMP module with 4 EMP units each

Put together your own personal airmatic system for your coating system. With up to 5 EMP modules, you can also equip several coating lines with one airmatic system.

Available as optional extensions:

airmatic also for your application!

With the various system variants and options of our modular system, we can offer the right solution for you! Use the expertise of our experienced technicians and optimize your coating processes.