As part of a field test, the influence of airmatic on the practical application of a clear coat on plastic and metal substrates was scientifically determined.

Distribution of mean droplet size Dv(50)

Using laser diffraction spectrometry, it was demonstrated that the radial distributions of the mean droplet sizes become significantly homogeneous and that an increasing refinement of the spray towards the edge no longer occurs.

Layer thickness width at half maximum layer thickness (Sb50) and application efficiency (AWG)

Despite constant air volumes, there is a change in the layer thickness distribution. The characteristic jet width Sb50 increases by approx. 15-25% thanks to the airmatic. In addition, the application efficiency increases by 5-6.5%.

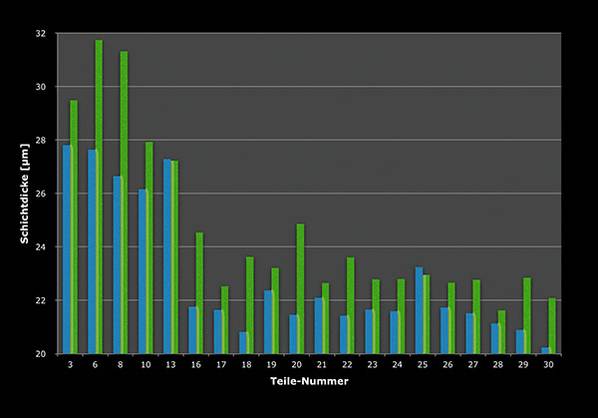

Average layer thicknesses

Overall, an increase in the average layer thickness of between 5 and 15 % was found. The amount of paint can be reduced by approximately these values, which ultimately enables potential paint savings.

Conclusion

The results mentioned were achieved WITHOUT changing the application parameters. In this case, this results in paint savings of between 5 and 15 percent. No negative change in the appearance or paint structure could be detected.