airmatic atomization optimization

Reduce paint consumption and increase quality!

The airmatic atomization optimization can be used wherever air atomization or air-assisted painting and coating is used!

Thomas Mayer, Managing Director of ensutec Products GmbH and head of innovations, explains: “We have continuously developed and perfected the innovative EMP technology as the core of our systems. Today we are presenting the latest generation of airmatic atomization optimization to the market as a comprehensive technology for the reliable, high-quality application of paints and coating materials all year round."

It is now used by car manufacturers and suppliers, by repair and body painters, in the wood and furniture industry, in industrial painting and in textile and leather companies as well as in many other areas.

Can be retrofitted to any system – suitable for any application process

“With the unique EMP technology you achieve excellent results in paint atomization and surface quality!”

The airmatic atomization optimization also works in addition to the existing application technology. It can be retrofitted at any time without great effort. As a rule, no significant changes to the painting system are necessary.

As part of our modular system, we offer you the opportunity to select the optimal system technology for you. With just a few questions you can find the right technical equipment for you!

Is that really true?

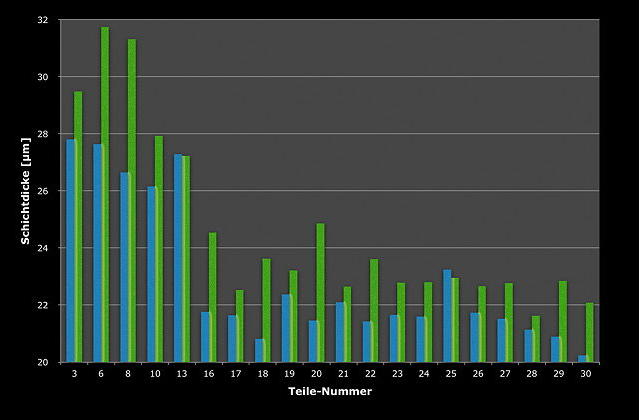

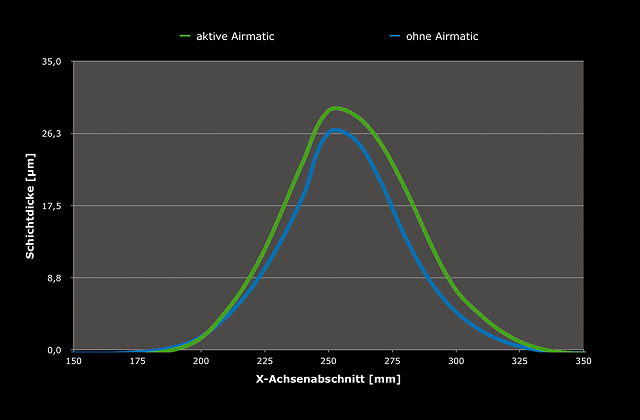

The paint manufacturer has investigated how the airmatic atomization optimization affects the number of dirt particles on metal and plastic parts. Axalta in its automotive technology center. For this purpose, metal sheets and plastic panels were extensively coated with base coat and clear coat – with normal atomizing air and atomizing air prepared with EMP technology.

It was shown that the airmatic atomization optimization reduced the dirt influences on sheet metal by about 10 percent and on plastic by about 30 percent.

In addition, a higher application efficiency was recorded with comparable application parameters, a resulting paint saving of 10 percent and a trend towards better surface finish.

Scientifically proven: EMP technology works!

From 2016, ensutec Products GmbH had the airmatic atomization optimization tested as part of a scientific research project at the Esslingen University of Applied Sciences (details of the positive results can be found here).