airmatic atomization optimization

The innovation for hand painting

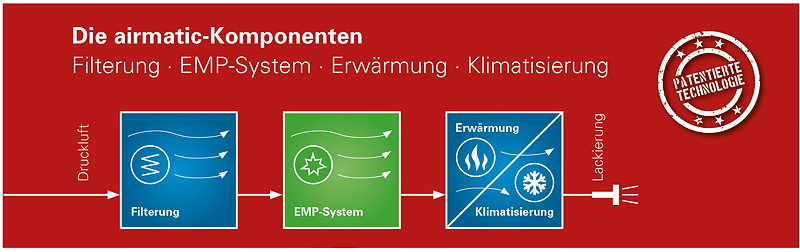

With the scientific investigation of EMP technology and the resulting further development of the components of our airmatic systems, we have achieved a quantum leap for manual application.

For manual application

The additional technical components provide all the prerequisites for high-quality and year-round reliable application of paints and coating materials.

The advantages of airmatic atomization optimization

- High paint quality

- Paint savings of 10 to 20%

- Process reliability

- Material and energy efficiency

- Better course

- Less dust and dirt inclusions

- Better paint level

- Pleasant painting conditions

- Capacity increase

- Rapid amortization

And the painter does not have to change his working methods when using the airmatic atomization optimization!

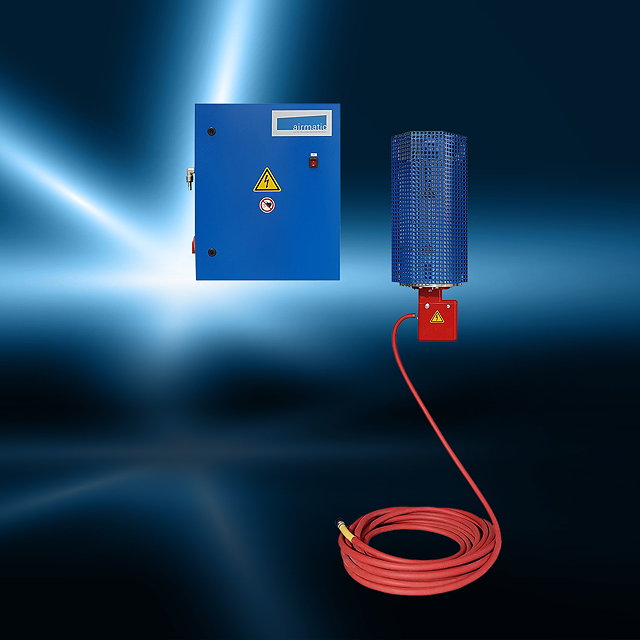

Easy and quick to install

- In addition to the existing application technology

- Can be retrofitted at any time without great effort

- Usually no significant changes to the painting system are necessary